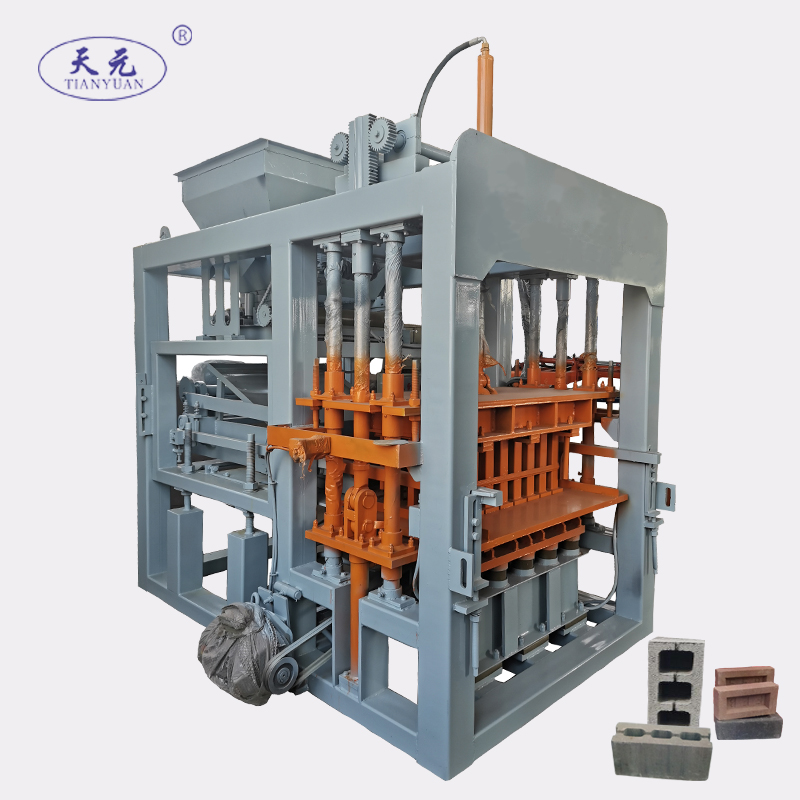

Automatic block machine production line QTY4-15

- 1.block machine QTY4-15 Feathures:

(1) Manual and electric control, easy to operate.

(2) The four-rod guide method and long guide bearing are used to ensure the accurate movement of the indenter and mold.

(3) The block machine body is made of strong steel and special welding technology and materials, making it strong and shock-resistant.

(4) The mold can be quickly changed to produce cement products of different specifications and shapes such as pavement bricks, curb stones, hollow blocks, and standard bricks. One machine can be used for multiple purposes.

(5) Imported seals and some hydraulic components make the overall performance of the equipment stable and reliable.

(6) The motor adopts a pure copper core motor, and the oil cap adopts a special oil cap for large hydraulic machinery.

(7) Mechanical transmission, compact and easy to maintain, flexible in operation and good in reliability.

(8) Pressurize up and down and vibrate vigorously, especially to produce load-bearing high-strength blocks (strength up to 26MPa).

- 2.Block machine specifications:

| Dimension(L*W*H) | 3470×1680×2700mm | Vibration force | 45KN |

| Hydraulic pressure | 16Mpa | Weight | About 4500KG |

| Moulding period | 15S | Vibration Frequency | Max.4900r/m |

| Power | 28.7KW | Palle size(mm) | 900×550 |

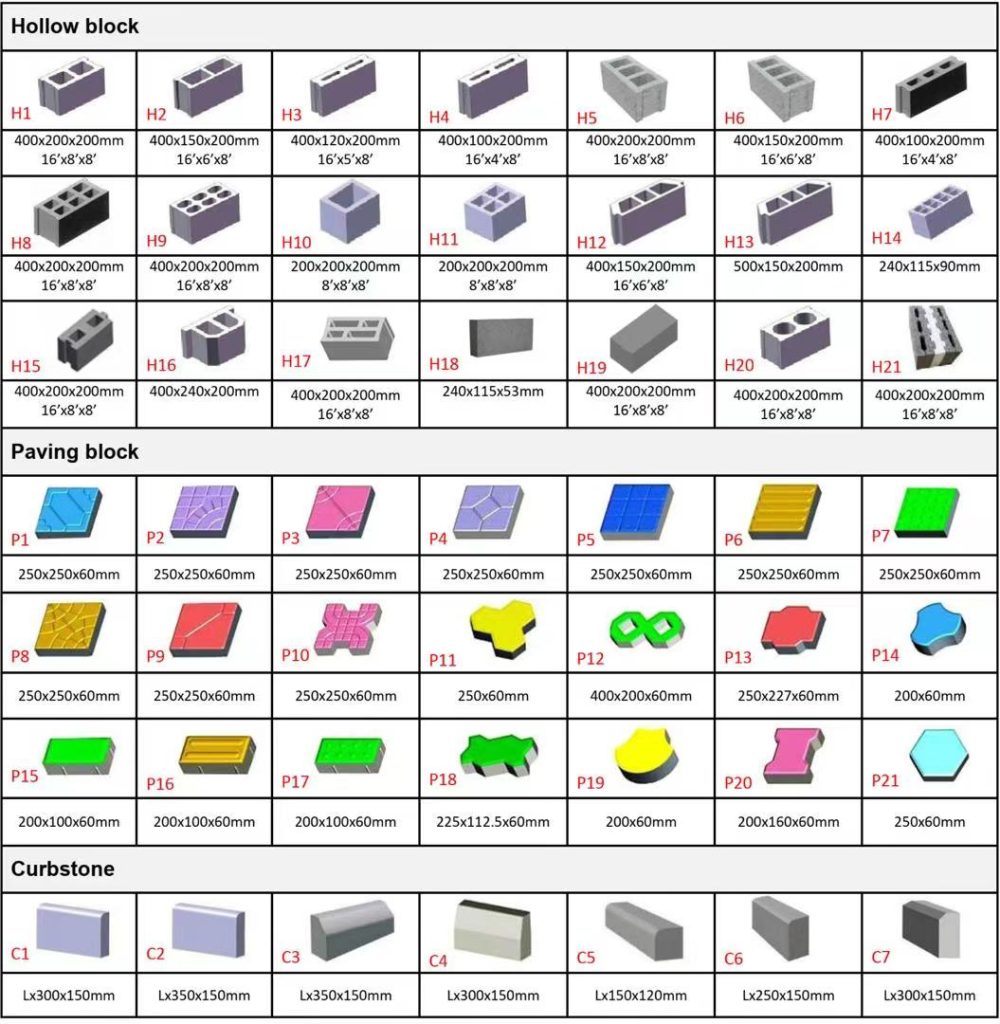

- 3.Block machine products Sample

- 4.Block machine QTY4-15 Capacity reference:

| Size(LxWxH) mm | Pcs/Mould | Pcs/hr | Pcs/ 8Hr |

400X200X200 hollow block | 4 | 960 | 7860 |

400X150X200 hollow block | 5 | 1200 | 9600 |

400X100X200 hollow block | 8 | 1920 | 15360 |

240X115X53 solid brick | 26 | 6240 | 49920 |

200x100x60 paver brick | 14 | 2520 | 20160 |

225×112.5X60 paver brick | 12 | 2160 | 17280 |

200X160X60 paver brick | 8 | 1440 | 11520 |